Blood Plasma Fractionation Expertise

by Masco Group

Leading the Way in Comprehensive Blood Plasma Solutions - At Masco Group, blood plasma fractionation is more than a specialty—it's a testament to our holistic approach. We excel at separating blood plasma into essential components—such as clotting factors, albumin, immunoglobulins, and antibodies—customized to address a variety of medical conditions, including immune disorders and hemophilia. Our dedication to technology and innovation, combined with the extensive know-how and experience of our companies, embodies the concept of a complete solution throughout the entire process value chain. This ensures enhanced efficiency and safety for these critical, life-saving products.

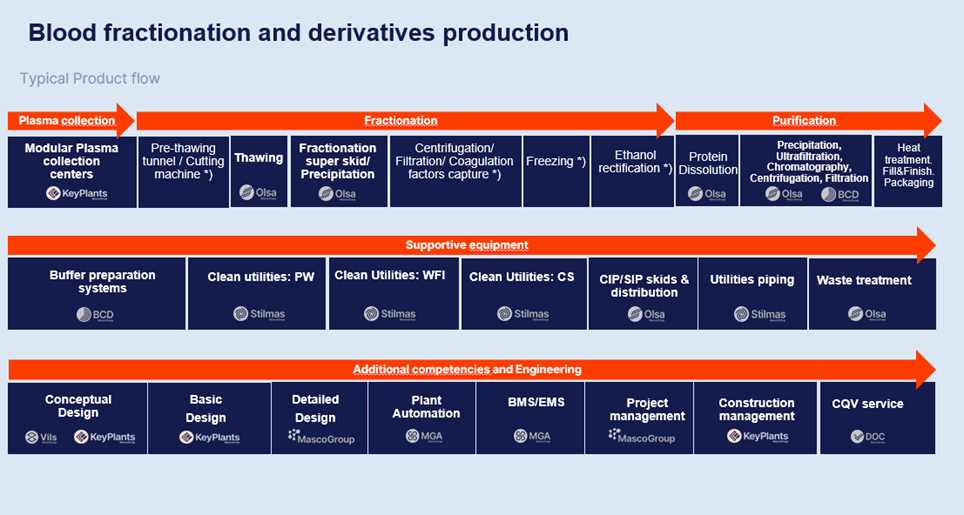

Customizable Fractionation Process - Our blood plasma fractionation process is highly adaptable, designed to meet the specific needs of each client to ensure optimal outcomes. Below is an illustrative example of a typical process flow, showcasing our comprehensive capabilities:

Click on image to view a bigger version.

*) In the example above, where no Masco Group companies are mentioned, the activities will be managed by a trusted third-party contractor, with Masco Group serving as the main contractor.

Typical Process Flow: Blood Plasma Fractionation Process at Masco Group

1. Plasma Collection

- Modular Plasma Collection Centers: Designed and equipped by Masco Group’s company, KeyPlants, to ensure optimal efficiency and safety in plasma collection.

2. Fractionation

- Thawing: Utilizing advanced technology from Masco Group’s Olsa, we ensure continuous, rapid and consistent thawing with accurate temperature control, which is crucial for maintaining protein integrity.

- Fractionation Super Skid/Precipitation: Engineered by Olsa to manage ethanol addition precisely for protein precipitation ensuring high process yield.

- Centrifugation/Filtration/Coagulation Factors Capture: These critical steps ensure the isolation and purification of specific plasma components.

- Freezing and Ethanol Rectification: Final processing steps to stabilize and store the plasma components for further use.

3. Purification

- Protein Dissolution: Thanks to Olsa expertise in thawing, we ensure quick and consistent dissolution of proteins in this first critical step of purification

- Advanced Purification Processes: Including precipitation, ultrafiltration, chromatography, centrifugation, and filtration, handled by Masco Group’s companies BCD and Olsa, to ensure the highest purity and functionality.

- Heat Treatment, Fill & Finish, Packaging: Final preparations for the plasma components to be ready for medical use, ensuring safety and efficacy.

4. Supportive Equipment

- Buffer Preparation Systems: Provided by BCD to prepare solutions that aid in plasma processing.

- Clean Utilities: Managed by Stilmas, including purified water (PW), water for injection (WFI), and clean steam (CS), vital for maintaining a sterile processing environment.

- CIP/SIP Skids & Distribution: Designed by Olsa to facilitate the cleaning and sterilization of process equipment and piping.

- Utilities Piping: Ensured by Stilmas to provide necessary services throughout the facility.

- Waste Treatment Systems: Developed by Olsa to handle and treat waste products from the fractionation process safely and efficiently.

- Transfer panel and valve block array: provided by BCD, Olsa to ensure maximum flexibility in fractionation and purification processes

- Temperature control units: provided by Olsa to grant accurate temperature control for thawing and precipitation tanks, but also for third party centrifuge systems

5. Additional Competencies and Engineering

- Conceptual and Basic Design: Carried out by Masco Group’s VILS and KeyPlants to establish the foundational design parameters and overall layout of the fractionation facility.

- Detailed Design: Executed by Masco Group to finalize all aspects of the engineering design.

- Plant Automation and Control Systems: Implemented by Masco Group Automation (MGA) to enhance process control and ensure compliance with the highest standards and regulatory compliance.

- Building Management Systems/Environmental Monitoring Systems (BMS/EMS): MGA integrate the automation layer with BMS/EMS.

- Project and Construction Management: Managed in-house by Masco Group and KeyPlants to ensure projects are delivered on time, within budget, and meet all regulatory requirements.

- Commissioning, Qualification, and Validation (CQV) Service: Provided by DOC to verify and validate the facility and equipment performance.

- Digital Solutions: comprehensive digital solutions by Masco Group Automation (MGA), powered by AI, designed to optimize pharmaceutical operations, consumption and overall efficency

Our Unwavering Commitment to Blood Plasma Fractionation

Blood plasma fractionation is more than a service at Masco Group—it’s our specialty. We are committed to ensuring that each facility we design and equip meets rigorous standards of safety, efficacy, and quality, making a significant impact on patient lives worldwide.

To see one of our reference cases please visit this link: MasterPlasma, Plasma Fractionation Facility | Keyplants

Contact Us

Discover the Masco Group difference in blood plasma fractionation and purification. Contact our experts today for a detailed consultation or visit our facilities to witness our commitment and expertise firsthand, and learn how we can tailor the fractionation and purification processes to meet your specific needs.